Smart manufacturing is the use of information technology and data analytics to improve the efficiency, flexibility, and transparency of manufacturing operations. It is a rapidly evolving field, driven by the increasing connectivity of machines, sensors, and people.

There are many benefits to smart manufacturing. It can help manufacturers to:

- Reduce costs by improving efficiency and waste reduction

- Improve quality by reducing defects and increasing product traceability

- Increase flexibility by enabling faster product changeovers and more responsive production

- Gain insights into their operations by collecting and analyzing data

- Make better decisions by using data to identify trends and opportunities

As a result of these benefits, smart manufacturing is becoming increasingly important for manufacturers who want to stay competitive. In fact, a recent report by the World Economic Forum found that smart manufacturing could add $15 trillion to the global economy by 2025.

There are a number of technologies that are driving the adoption of smart manufacturing. These include:

- The Internet of Things (IoT): The IoT connects machines, sensors, and people to the internet, allowing them to share data and communicate with each other.

- Big data analytics: Big data analytics can be used to analyze the data collected from the IoT to identify trends, patterns, and anomalies.

- Cloud computing: Cloud computing provides a platform for storing and processing data, making it accessible to manufacturers from anywhere in the world.

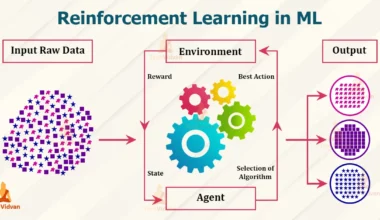

- Artificial intelligence (AI): AI can be used to automate tasks, make predictions, and optimize processes.

These technologies are not only enabling smart manufacturing, they are also creating new opportunities for manufacturers. For example, manufacturers can use AI to develop predictive maintenance models that can identify potential problems with machines before they fail. This can help to prevent unplanned downtime and reduce costs.

The future of manufacturing is bright. As smart manufacturing technologies continue to evolve, manufacturers will be able to improve their operations in ways that were not possible before. This will lead to increased productivity, efficiency, and quality, which will benefit both manufacturers and consumers.

Here are some specific examples of how smart manufacturing is being used today:

- GE Aviation is using smart manufacturing to improve the production of jet engines. By connecting sensors to the engines, GE is able to collect data on how the engines are performing. This data is then used to identify potential problems and make predictions about future performance.

- Volvo Cars is using smart manufacturing to personalize its cars. By collecting data on customer preferences, Volvo is able to customize the features of its cars to the individual needs of each customer.

- Nike is using smart manufacturing to track the performance of its shoes. By embedding sensors in its shoes, Nike is able to collect data on how the shoes are being used. This data is then used to improve the design and performance of future shoes.

These are just a few examples of how smart manufacturing is being used today. As the technology continues to evolve, we can expect to see even more innovative applications of smart manufacturing in the future.

Of course, there are also some challenges that manufacturers will need to overcome in order to fully adopt smart manufacturing. These challenges include:

- Cost: The cost of implementing smart manufacturing technologies can be high. However, the long-term benefits of smart manufacturing can outweigh the initial costs.

- Data security: The data collected from smart manufacturing systems is valuable. It is important to protect this data from unauthorized access.

- Skills gap: There is a shortage of skilled workers who are able to implement and operate smart manufacturing technologies. This is a challenge that manufacturers will need to address in order to fully adopt smart manufacturing.

Despite these challenges, the future of smart manufacturing is bright. As the technology continues to evolve and the cost of implementation decreases, we can expect to see more and more manufacturers adopting smart manufacturing. This will lead to a more efficient, flexible, and transparent manufacturing industry that benefits both manufacturers and consumers.thumb_upthumb_downuploadGoogle itmore_vert